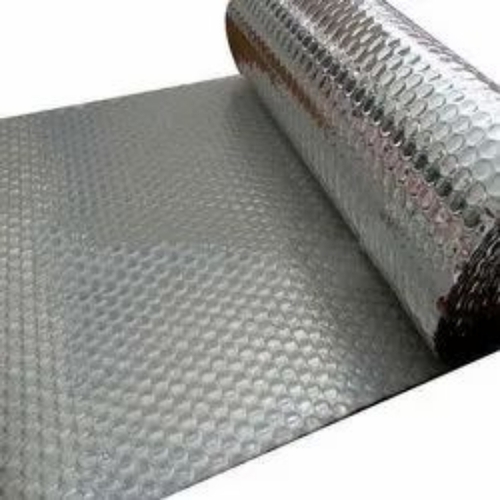

BUBBLE INSULATION

Price 80 INR/ Square Meter

BUBBLE INSULATION Specification

- Surface Treatment

- Aluminum Foil Coated

- Coating Type

- Metalized Aluminum Foil

- Feature

- Moisture Barrier, Fire Retardant, Eco-friendly, Light Weight

- Size

- Standard rolls of 1.2 m x 40 m (Custom sizes available)

- Density

- 30 Gram per cubic centimeter(g/cm3)

- Layer

- Single, Double, or Triple Bubble option

- Thermal Conductivity

- 0.033 W/mK

- Installation Guideline

- Install with foil face towards heat source; overlap, tape and staple or fix mechanically to substrate

- Product Type

- Thermal Insulation Sheet

- Material

- Metalized Polyethylene with Air Bubble Layer

- Tensile Strength

- ~380 kPa

- Width

- 1.2 m

- Thickness

- 4 mm to 10 mm

- Application

- Roof, Wall, Duct, HVAC, Industrial Sheds, Cold Storage, Warehouses

- Heat Conductivity

- 0.033 W/mK

- Color

- Silver

- Max Withstanding Temperature

- -50C to +110C

- Standards Compliance

- ASTM, EN, IS standards (varies by model)

- Sound Insulation

- Yes (Provides sound dampening)

- Corrosion Resistance

- Excellent

- Weight per Roll

- Approx. 1025 kg, depending on thickness

- Moisture Resistance

- High

- UV Resistance

- Yes (with proper installation)

- Reflectivity

- >97%

- Packaging Type

- Roll

- Fire Class

- Class 0/Class 1 (as per BS 476 Part 6 & 7)

- Recyclability

- 100% recyclable

- Water Vapour Transmission

- <0.01 perm

About BUBBLE INSULATION

Bubble insulation, also known as reflective bubble insulation or bubble wrap insulation, is a type of insulation material that consists of a layer of small airfilled bubbles sandwiched between two layers of reflective material, such as aluminum foil. It is commonly used to provide thermal insulation in various applications.

The airfilled bubbles in bubble insulation act as a barrier to reduce heat transfer through conduction and convection. The reflective surfaces on both sides of the material help to reflect radiant heat, further enhancing its insulating properties. This combination of reflective and insulating properties makes bubble insulation effective in reducing heat loss or gain, depending on the desired application.

Outstanding Fire and Thermal Protection

Certified to BS 476 Class 0/Class 1 standards, this bubble insulation resists fire and provides high thermal reflectivity (>97%), minimizing energy transfer through roofs, walls, and ducts. With a low thermal conductivity of 0.033 W/mK, it keeps interiors cooler in summer and warmer in winter, enhancing overall comfort and safety.

Versatile Applications Across Industries

Ideal for use in industrial sheds, HVAC ducts, warehouses, cold storage, and residential or commercial roofs and walls, this insulation adapts to multiple settings. The aluminum foil-coated surface acts as a moisture barrier, while superior tensile strength (~380 kPa) ensures durability during installation and operation.

Eco-Friendly and Easy to Install

Manufactured from fully recyclable materials, this insulation is environmentally responsible from fabrication through to disposal. Standard rolls (1.2 m x 40 m) simplify handling, while the user-friendly installation methodoverlapping, taping, and stapling with foil facing the heat sourceenables both professionals and DIY enthusiasts to achieve effective thermal barriers.

FAQs of BUBBLE INSULATION:

Q: How should bubble insulation with metalized aluminum foil be installed for optimal performance?

A: To maximize efficiency, install the insulation with the foil side facing the primary heat source. Overlap edges by a few centimeters, secure joints with aluminum tape, and mechanically fix or staple the material to the substrate. Ensure a tight fit, particularly in corners and around ducts, for the best thermal and moisture barrier.Q: What are the primary benefits of using Class 0/Class 1 fire-rated bubble insulation?

A: This insulation provides outstanding fire safety as it complies with stringent Class 0/Class 1 standards per BS 476. Alongside high thermal reflectivity and robust sound dampening, it offers superior moisture, UV, and corrosion resistance, making it highly suitable for a range of demanding industrial and commercial environments.Q: Where can bubble insulation be effectively applied?

A: Bubble insulation is versatile and can be installed in roofs, walls, HVAC ducts, industrial sheds, warehouses, and cold storage facilities. Its lightweight rolls and customizable sizes make it easy to adapt to varied residential, commercial, and industrial structures.Q: What is the water vapour transmission rate, and why is it important in insulation?

A: The insulations water vapour transmission is less than 0.01 perm, meaning it acts as an excellent vapour barrier. This prevents moisture infiltration which can otherwise result in mold, reduced insulation efficiency, and structural damage.Q: Is this bubble insulation material environmentally friendly?

A: Yes. Made from recyclable metalized polyethylene and aluminum foil, the insulation is 100% recyclable, supporting sustainability from manufacturing to end-of-life disposal.Q: What sound insulation properties does the product offer?

A: In addition to thermal performance, this bubble insulation delivers sound dampening, making it beneficial for environments where noise reduction is a priority, such as industrial facilities, HVAC ducts, and even residential spaces.Q: When should this insulation be replaced or maintained?

A: Due to its excellent corrosion, moisture, and UV resistance, bubble insulation requires minimal maintenance. Regular inspections every few years are recommended, especially after significant temperature changes or construction activity, to ensure integrity and continued performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 07BNQPP0629C1ZZ

|

GREEN METAL INFRA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry